Fully Automatic Vehicle Bumper Beam Roll Forming Production Line

Overview Vehicle Bumper Beam Machine Vehicle Front Bumper Beam Roll Forming Machine Product Description Production proce

Overview

Production process flow

Uncoiling-leveling-servo feeding-on-line punching (various pass types)-cold forming-on-line welding-tracking and cutting.

Application

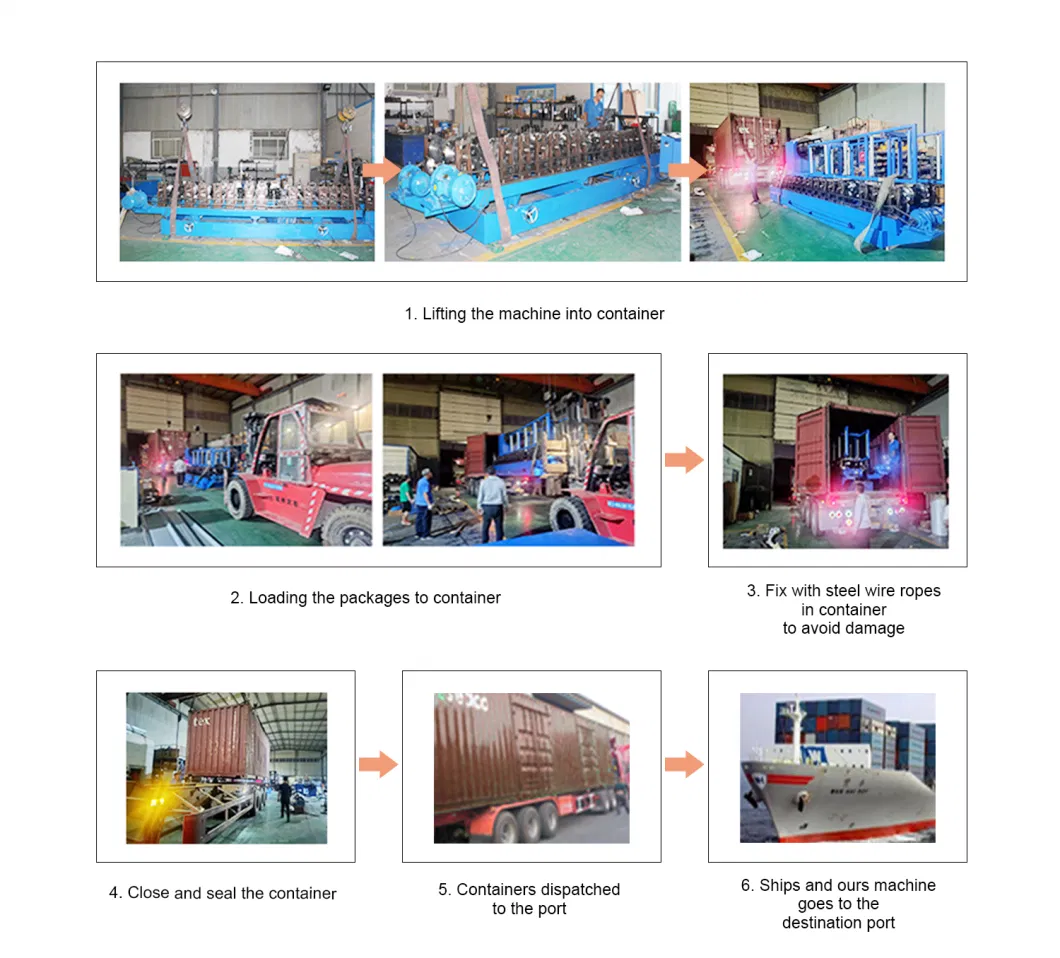

Packaging & Shipping

A: We assure each machine dispatched from our factory a long-life usage with easy operation and humane design.We consider help our customer to hence the production efficiency and save your human power as our aim.

2. How l believe you?

A: Welcome to visit us to check our plant and ability, the payment method can be chosen and the third party inspection through Alibaba is available.

3. What about the warranty of your products?

A: We provide 12 months warranty since the machine arrived at customer site , free charge of spare parts and oline maintenance service

4. Where are you? Can l visit you?

A: our factory located in Shandong province, china, welcome to visit us at any time.

5. How about the delivery time?

A: For standard model, the delivery usually 25 days since the advance payment receipt. For the customized products, the delivery time will follow our agreement with customer.We never receive any complain from our customers for the delivery time

6. What kind of payment does your company support?

A: TT,100% LIC at sight,Cash, Western Union are accepted. If you have other payment terms, welcome discuss with us

Basic Info.

| Type | Special Casting |

| Transport Package | 20/40 Feet Container or Wood Case |

| Specification | 20m * 2m |

| Trademark | Raintech |

| Origin | China |

| Production Capacity | 200 Per Month |

Product Description

Vehicle Bumper Beam Machine Vehicle Front Bumper Beam Roll Forming MachineProduct Description

Production process flow

Uncoiling-leveling-servo feeding-on-line punching (various pass types)-cold forming-on-line welding-tracking and cutting.

PRODUCTION PARAMETER

| No | Items | Specification |

| 1 | Model | SART-C89 |

| 2 | Coil OD | 1300 mm |

| 3 | Coil ID | 450-530mm |

| 4 | Coil Thickness | 0.8-1.2mm |

| 5 | Carrying Weight | 3 ton |

| 6 | Forming Passes | 8 dots |

| 7 | Production Speed | 0-15m/min |

| 8 | Machine Power | 15KW |

| 9 | Cover Space | 12000*2000*1800mm |

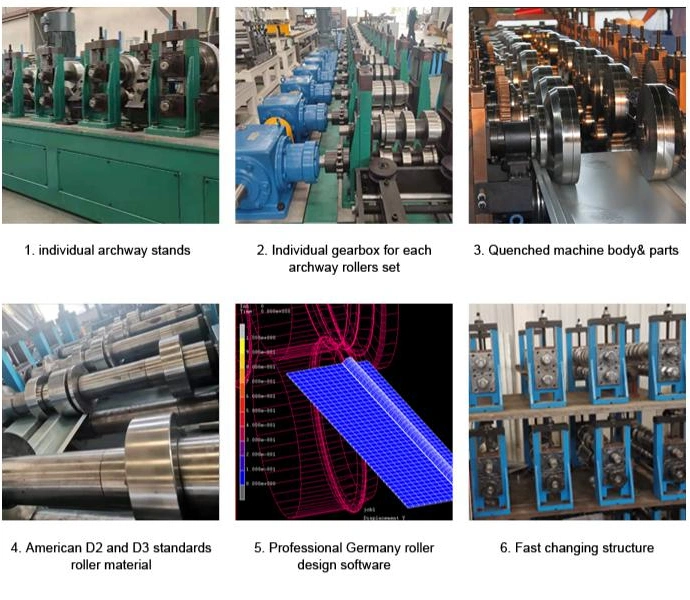

MACHINE COMPONENTS

| No | Items Name | Specifications |

| 1 | Decoiler | Single head mode, single supportCoil ID: Ф508Coil OD: Ф1300mmStrips width: 1450 mmMax. weight: ≤10000 kg |

| 2 | Roll Forming Machine | Structure: the forming unit is driven by motor reducer chainForming stations:36 stationsForming machine shaft dia:φ95mmMotor power: 22kwX2Max.: 15m/min |

| 3 | Hydraulic Cutting | The cutter mode adopts blanking shearingBlade material :Cr12MoV (hardness after quenching HRC58~62)Parameter :cutting accuracy:±1.5mm |

| 4 | Electrical Control Cabinet | Main electrical components:PLC: MitsubishiInverter: deltaTouch screen: veron (Taiwan, China)Low-voltage electrical appliances: Schneide (France)Encoder: Omron (Japan) |

| 5 | Hydraulic System | Hydraulic system USES filter, the cleanliness of oil to ensure 6-8 grade |

| 6 | Run-out Table | Size:3*1.2*0.6mAdjustable Height |

Description of Machine component

| Material | Pregalvanized GI and CR |

| Yield strength of raw materials | 235Mpa |

| Tensile strength of raw materials | 550Mpa |

| Coil OD | ≤Ф1300 mm |

| Coil ID | Ф508mm |

| Strip width | ≤100mm |

| Strip thickness | ≤1~2.25mm |

| Single roll weight | ≤1000 kg |

WORKPIECE

Packaging & Shipping

A: We assure each machine dispatched from our factory a long-life usage with easy operation and humane design.We consider help our customer to hence the production efficiency and save your human power as our aim.

2. How l believe you?

A: Welcome to visit us to check our plant and ability, the payment method can be chosen and the third party inspection through Alibaba is available.

3. What about the warranty of your products?

A: We provide 12 months warranty since the machine arrived at customer site , free charge of spare parts and oline maintenance service

4. Where are you? Can l visit you?

A: our factory located in Shandong province, china, welcome to visit us at any time.

5. How about the delivery time?

A: For standard model, the delivery usually 25 days since the advance payment receipt. For the customized products, the delivery time will follow our agreement with customer.We never receive any complain from our customers for the delivery time

6. What kind of payment does your company support?

A: TT,100% LIC at sight,Cash, Western Union are accepted. If you have other payment terms, welcome discuss with us

Send to us