Integral Function 3 in 1 Assembly Welding Straightening I H Beam Machine

Overview Package Size 2800.00cm * 600.00cm * 400.00cm Package Gross Weight 12000.000kg A. Usage and Application:1. This

Overview

A. Usage and Application:1. This machine is for producing welding H Beam T Beam with single equipment;2. Max. size of H Beam T Beam: Web height 1500mm/ 1800mm/ 2000 mm, flange thickness 40mm;(Fig.1,2,3) See as below:3. Related product: H Beam Production Line

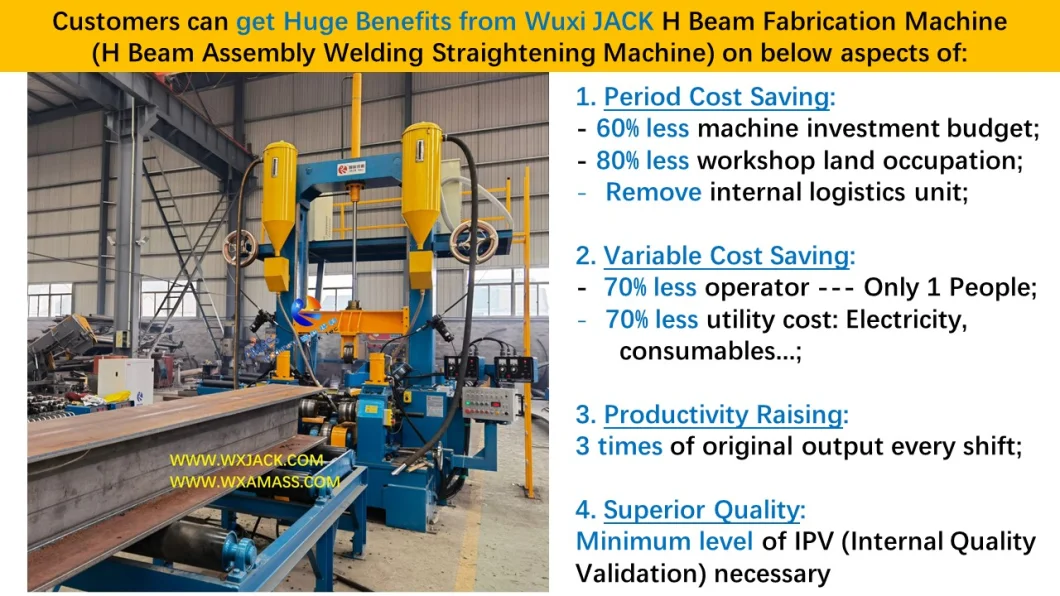

B. Advantages of Wuxi JACK (Wuxi AMASS) 3 in 1 H Beam Fabrication Machine:

This is superior product of Wuxi JACK (Wuxi AMASS). Below slides gives clear introduction on our superiorities:

C. Category and Model:1. Wuxi JACK (Wuxi AMASS) manufactures 2 series: PHJ and ZHJ:1) PHJ models produce both symmetric and asymmetric cross section H Beam; (Fig.4)2) ZHJ models produce symmetric cross section H Beam;2. Standard models: PHJ15/PHJ18/PHJ20; ZHJ8015/ ZHJ8018/ ZHJ8020;3. Special model is available, such as ZHJ5010 for building small H Beam T Beam.

D. Main Units:

One set of the machine has 5 main units:1. Function units: Assembling, Welding, Straightening; 2. Mechanical frame;3. Input and output conveyors;4. Hydraulic system;5. Electric control system;

E. Wuxi JACK (Wuxi AMASS) Position in the Realm of Delivering 3 in 1 H Beam Assembly Welding Straightening Integral Machine for Customers: 1. In 2009, Wuxi JACK is the 1st company in industry to successfully develop H Beam Fabrication Machine from concept design to mature application, and put it into market. Ever since, it gained more and more customer recognition both in China and Overseas market;2. Over past decades, technical performance and market share of our product always rank top in industry, both in China and Overseas market.

F. Technical Parameters:

Technical Parameters

Our AdvantagesAfter Sales ServiceFAQ1. Q: What is the relationship between Wuxi AMASS and Wuxi JACK?

A: Wuxi AMASS and Wuxi JACK are the same company: Wuxi AMASS is wholly owned subsidiary of Wuxi JACK, for overseas trading Wuxi JACK products;

2. Q: What is the nature of your company?

A: Business scope of Wuxi JACK and AMASS covers design, production and selling;

3. Q: What is the range of your company product?

A: Wuxi JACK and AMASS is a professional supplier in Welding and Cutting Industry;Main products of our company include:1) Steel structure production equipment (H Beam/ BOX Beam/ T Beam);2) Edge Milling Machine;3) Structure member Beam end face milling machine;4) CNC Plate Cutting Machine;5) CNC Pipe Cutting Machine;6) Various kinds of conventional and special design welding equipment and machine;7) Various kinds of conventional and special design Straightening machine, etc.;

4. Q: What is the strength of your company?

A:1) Wuxi JACK was founded by 3 senior engineers 15 years ago;2) Engineering team of our company has over 20 years experience on Welding and Cutting industry;3) Operation manager has 14 years experience working in an American Fortune Global 500 Dow Jones Industrial Index Company as senior Project Manager;4) The competitive edge of our company is special design products based on customer demand.

5. Q: What are service terms of your company?

A:1) During business negation: a) Make technical proposal and quotation;b) Answering customer questions;c) Make final contract and technical agreement;2) During order to delivery value chain:a) Design, validate, and manufacture products for customers;b) Inform progress of manufacture to customers;c) Arrangement for package and shipment of products to customers;3) After sale service: a) Technical support on installation and commissioning at customer site;b) 1 year guarantee from the date of acceptance;c) Feedback any technical issues within 4 hours upon getting the notice;

6. Q: Where is location of your company?

A: Wuxi city, Jiangsu province, 130km from Shanghai

Basic Info.

| Model NO. | PHJ15/ 18/ 20 and ZHJ8015 ~ 8020 /5010 |

| Certification | ISO, CE |

| Automation | Automation |

| Flexible Production | Lean Production |

| Rhythm | Flow Production Line |

| Production Scope | Parts Production Line |

| After-sales Service | 1 Year Gurantee, Life Long Technical Support |

| Welding Torch Control | 3 dimensional precise |

| Down Pressing Roller | Heavy duty high precision guiderail |

| Flange Width | Up to 800 mm |

| Web height | Up to 2000mm |

| Machine Model | Standard and special design |

| Function Units | Welding power supply, flux recovery, wire feeder |

| Minimum flange thickness | 3mm |

| Workpiece cross section | Symmetric and Asymmetric |

| Finished Product | welding T Beam and H Beam |

| Advantage | Best Quality, Cost Effectiveness |

| Flange Thickness | Up to 40mm |

| Welding Position | Vertical |

| Function | Assembly Welding Straightening Integral |

| Working Style | Three in One Automatic |

| Welding | Submerged Arc Welding and CO2 Welding |

| Transport Package | Disassembled Into Wooden Case |

| Specification | NW/GW=11660/11765 kg, 32.16CBM |

| Trademark | Wuxi JACK and AMASS |

| Origin | Wuxi, China |

Packaging & Delivery

Package Size 2800.00cm * 600.00cm * 400.00cm Package Gross Weight 12000.000kgProduct Description

A. Usage and Application:1. This machine is for producing welding H Beam T Beam with single equipment;2. Max. size of H Beam T Beam: Web height 1500mm/ 1800mm/ 2000 mm, flange thickness 40mm;(Fig.1,2,3) See as below:3. Related product: H Beam Production Line

B. Advantages of Wuxi JACK (Wuxi AMASS) 3 in 1 H Beam Fabrication Machine:

This is superior product of Wuxi JACK (Wuxi AMASS). Below slides gives clear introduction on our superiorities:

C. Category and Model:1. Wuxi JACK (Wuxi AMASS) manufactures 2 series: PHJ and ZHJ:1) PHJ models produce both symmetric and asymmetric cross section H Beam; (Fig.4)2) ZHJ models produce symmetric cross section H Beam;2. Standard models: PHJ15/PHJ18/PHJ20; ZHJ8015/ ZHJ8018/ ZHJ8020;3. Special model is available, such as ZHJ5010 for building small H Beam T Beam.

D. Main Units:

One set of the machine has 5 main units:1. Function units: Assembling, Welding, Straightening; 2. Mechanical frame;3. Input and output conveyors;4. Hydraulic system;5. Electric control system;

E. Wuxi JACK (Wuxi AMASS) Position in the Realm of Delivering 3 in 1 H Beam Assembly Welding Straightening Integral Machine for Customers: 1. In 2009, Wuxi JACK is the 1st company in industry to successfully develop H Beam Fabrication Machine from concept design to mature application, and put it into market. Ever since, it gained more and more customer recognition both in China and Overseas market;2. Over past decades, technical performance and market share of our product always rank top in industry, both in China and Overseas market.

F. Technical Parameters:

| Model | PHJ15 | PHJ18 | PHJ20 | ZHJ8015 | ZHJ8018 | ZHJ8020 |

| Technical Parameter | Automatic H Beam Production machine (Fit Up Full I Beam Fabrication machine) | |||||

| Web height | 200∼1500/ 1800/ 2000 mm | |||||

| Web Thickness | 6∼32 mm | 5∼30mm | ||||

| Flange width | 200∼800mm | 150∼750mm | ||||

| Flange thickness | 6∼40 mm | |||||

| Workpiece length | 3 ∼15 m (This is just standard length. It can be tailor made) | |||||

| Welding Seam | One time pass of 8~12 mm toe size | |||||

| Working Speed | 200∼1200mm/min.(Continuous and Stepless)Consistent with Assembly, Welding, Straightening; A.C. Inverter control, variable frequency drive | |||||

| Welding Mode | Single Arc or Twin Arc SAW at fillet flat position; CO2 MIG/MAG; Tandem double arc SAW | |||||

| Workpiece | PHJ: Symmetric and Asymmetric; ZHJ: Symmetric only:Cross Section of Welding H Beam/ I Beam/ T Beam | |||||

| Drive | Main driving motor 5.5kW for Assembly and Straightening; Input and Output Conveyor motor: 1.1kW x 2 | |||||

| Hydraulic System | 4.4kW oil pump motor, working pressure 6~8MPa; Max. pressure 10MPa | |||||

| Input and Output Conveyor | 10~11m length in 3 segments each; One with motor, the other two follower-type; Standard length of input conveyor has three segments of machine hands; Output conveyor has one segment of elevation | |||||

| Machine size(L×W×H) | 28m×4m×4.6m | 28m×4m×4.9m | 28m×4m×5.1m | 28m×4m×4.2m | 28m×4m×4.5m | 28m×4m×4.8m |

Technical Parameters

Our AdvantagesAfter Sales ServiceFAQ1. Q: What is the relationship between Wuxi AMASS and Wuxi JACK?

A: Wuxi AMASS and Wuxi JACK are the same company: Wuxi AMASS is wholly owned subsidiary of Wuxi JACK, for overseas trading Wuxi JACK products;

2. Q: What is the nature of your company?

A: Business scope of Wuxi JACK and AMASS covers design, production and selling;

3. Q: What is the range of your company product?

A: Wuxi JACK and AMASS is a professional supplier in Welding and Cutting Industry;Main products of our company include:1) Steel structure production equipment (H Beam/ BOX Beam/ T Beam);2) Edge Milling Machine;3) Structure member Beam end face milling machine;4) CNC Plate Cutting Machine;5) CNC Pipe Cutting Machine;6) Various kinds of conventional and special design welding equipment and machine;7) Various kinds of conventional and special design Straightening machine, etc.;

4. Q: What is the strength of your company?

A:1) Wuxi JACK was founded by 3 senior engineers 15 years ago;2) Engineering team of our company has over 20 years experience on Welding and Cutting industry;3) Operation manager has 14 years experience working in an American Fortune Global 500 Dow Jones Industrial Index Company as senior Project Manager;4) The competitive edge of our company is special design products based on customer demand.

5. Q: What are service terms of your company?

A:1) During business negation: a) Make technical proposal and quotation;b) Answering customer questions;c) Make final contract and technical agreement;2) During order to delivery value chain:a) Design, validate, and manufacture products for customers;b) Inform progress of manufacture to customers;c) Arrangement for package and shipment of products to customers;3) After sale service: a) Technical support on installation and commissioning at customer site;b) 1 year guarantee from the date of acceptance;c) Feedback any technical issues within 4 hours upon getting the notice;

6. Q: Where is location of your company?

A: Wuxi city, Jiangsu province, 130km from Shanghai

:next

Send to us