Heavy Duty Industry H Beam Longitudinal Seam Welding Machine / Assembly Machine, H Beam Production Line*

Heavy Duty Industry H Beam Longitudinal Seam Welding Machine / Assembly Machine, H Beam Production Line* Product Descrip

Basic Info.

| Model NO. | HLT |

| Rated Capacity | Depends |

| Control Mode | Control Box and Remote Control |

| Flange Height | 200-1000 mm |

| Machine Type | Gantry Type |

| Welding Material | Steel, Aluminium Ect |

| Guide Rail Form | V Type Rail or Rectangular Type Rail |

| Application | Saw Arc Welding |

| Color | Blue & Yellow |

| Usage | H Beam Automatic Welding Machine |

| Welding Speed | 0.15-2.5 M/Min |

| Welder | Mz-1000 / DC-1000 |

| H Beam Length | 4000~15000mm or as Per User′s Request |

| Flange Width | 200-800mm |

| Product Name | Longitudinal or Circular Seam Welder for H Beam |

| Transport Package | Wooden Package for Arc Welding Machine |

| Specification | CE |

| Trademark | longterm |

| Origin | Wuxi, Jiangsu |

| HS Code | 85158090 |

| Production Capacity | 500 PCS / Per Month |

Product Description

Heavy Duty Industry H Beam Longitudinal Seam Welding Machine / Assembly Machine, H Beam Production Line*Product Description

This machine is designed according to special character of vessel welding,its mainly consist of Gantry frame,slide structure,welding gun tracking device,Flux recovery system,electrical control system and Submerged welding machine.

SAW Advantage

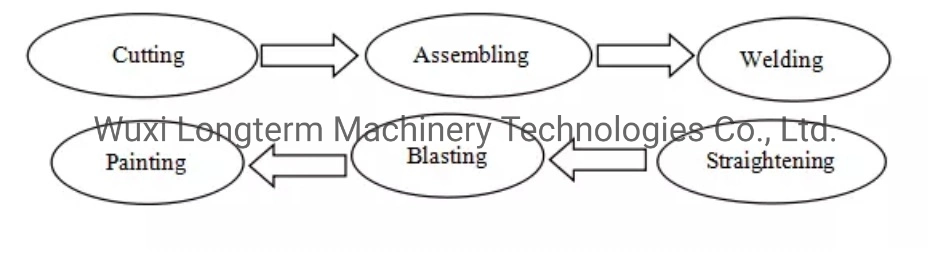

One of the top advantages of submerged arc welding is that it prevents hot materials from splattering and splashing onto workers.Another benefit is that the flux prevents high levels of radiation from being emitted into the air. Submerged arc welding does notrequire added pressure to weld because it is already generated by the electrode. This application is excellent for quickly weldingtogether thin metal sheets and creates a secure fusion between welds. This application also produces high productivity, fasttravel speed, high repeatability, and quality results.Process Flow

Details Images

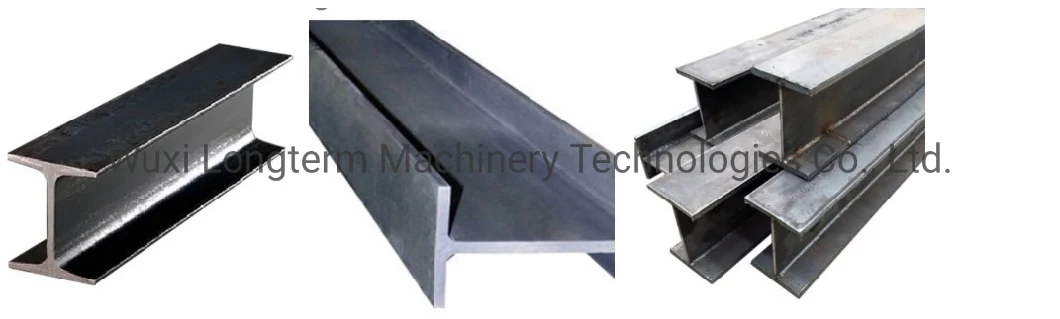

Finished Product

After-Sales Service.

If during warranty period: 1. If any damage for accessories or spare parts,we will provide for free. 2. If any damage for machine and machine doesn't work,we will send our engineer to repair. But customer needs to pay flight tickets,food and living. If beyond warranty period: 1. If any damage for accessories or spare parts,we will provide for free.But customer needs to pay flight charge. 2. If any damage for machine and machine doesn't work,we will send our engineer to repair. But customer needs to pay flight tickets,food,living and Salary (USD 80 per day).

Technical parameters

| Web beam height: | 200-1800mm |

| Web beam thickness: | 6-32mm |

| Flange beam width: | 200-800mm |

| Flange beam thickness: | 6-40mm |

| H beam length: | 4000-15000mm |

| Assembling speed: | 0.5-8m/min |

| Input roll: | 3000mm×3 |

| Output roll: | 3000mm×3 |

| Adjust method: | AC converter |

| Power: | 9 Kw |

Company Introduction

Our company is an experienced h beam production line manufacturer with 10 years.After many years' development ,H beam production line that we manufacture has compact structure,advanced functions and reliable quality. It is highly spoken of by customer because of its high automation.We also can design suitable h beam production line according to client's workshop and work piece with low price,reliable quality and thinkable service.

Machine packageOur team and Customers' visit

FAQ

- Q: Does one machine can only produce one size?

A: Not exactly, it depends on the machine.

− Q: Do you have after sales support?

A: Yes, we are happy to give advice and also have skilled technicians available to maintain the machine if needed.

− Q: What is the application of our products?

A: H beam SAW Welding

− Q: What can we offer our customers?

A: The products we offer are exactly according to CE and ISO Standard.

− Q: How long is the product warranty?

A: Warranty period of one year.

- Q:Do you provide customized?

A: Sure, we can design the equipment according to the data of the structural section you provide.

- Q: Do you have overseas engineers?

Yes, we not only provide overseas engineers, but also provide technical training.

Send to us