Automatic Steel Structure I H Beam Production Line Assembling Assembly Welding

Overview Package Size 10000.00cm * 6000.00cm * 400.00cm Package Gross Weight 50000.000kg A. Usage and Application: 1. HB

Overview

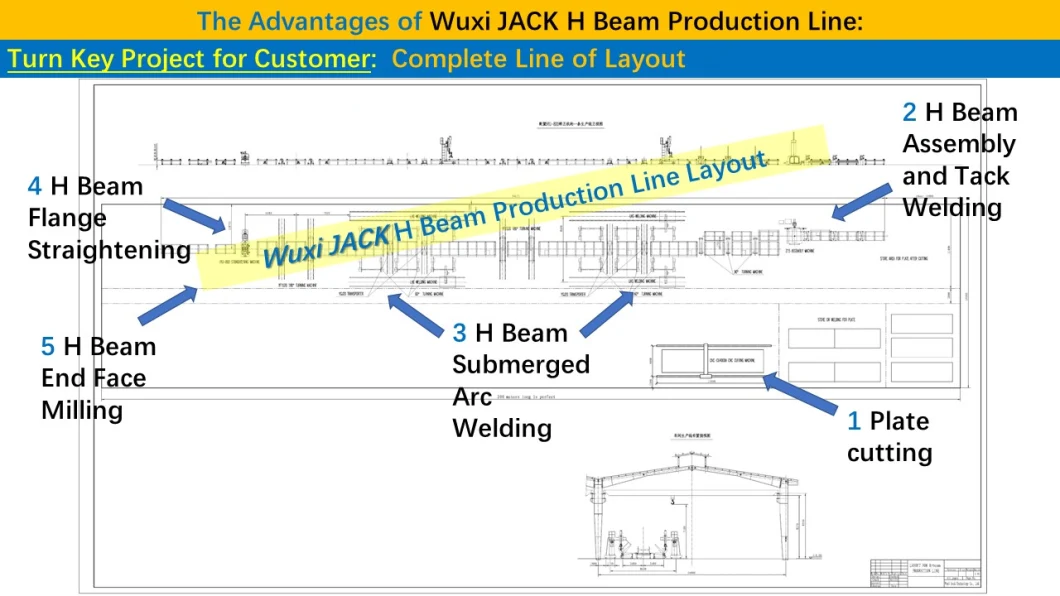

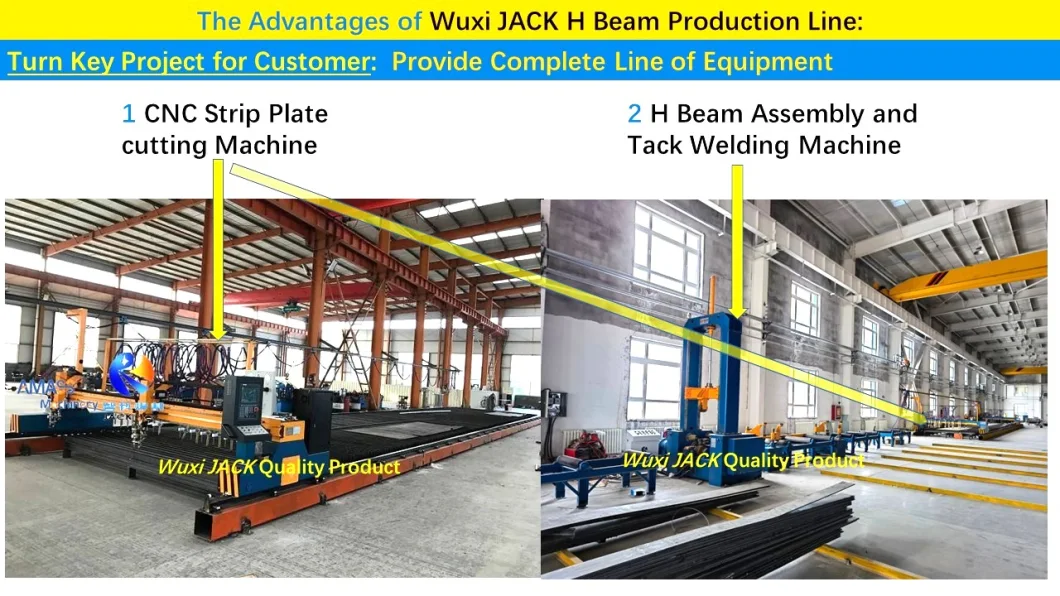

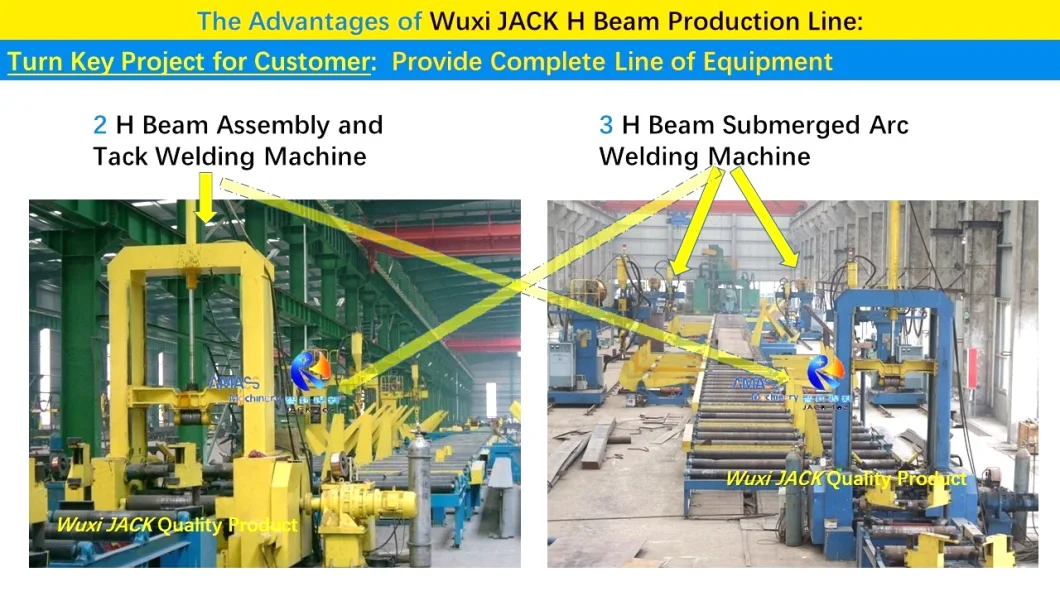

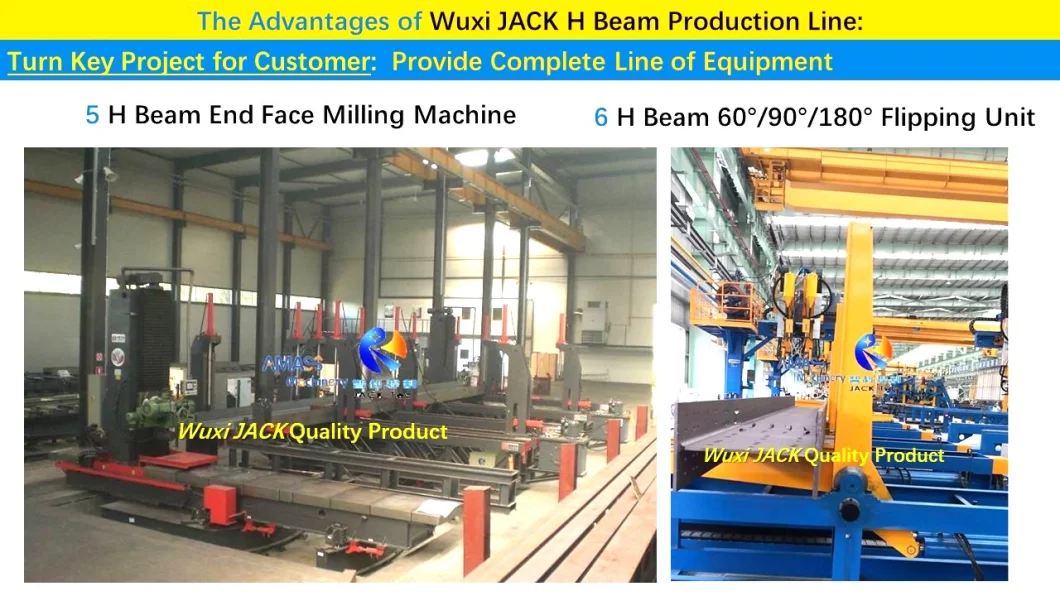

B. Advantages of Wuxi JACK (Wuxi AMASS) H Beam Production Line:

This is superior product of Wuxi JACK (Wuxi AMASS). Below slides give graphical introduction on our strong points:

C. Main Equipment in (Wuxi JACK) Wuxi AMASS H Beam Production Line: 1. CNC-CG4000A CNC Plate Cutting Machine 1 set1) Usage: For cutting steel plate into raw material2) Technical Parameters: (Fig.2) 2. Z15/ Z18/ Z20 H Beam Assembly and Tack Welding Machine 1 set1) Usage: For assembling and tack welding flange and web2) Technical Parameters: (Fig.3)

3. 90° Hydraulic Overturning Rack 3 sets/group1) Usage: For flipping WIP 90°2) Technical Parameters: (Fig.4)

4. LHC Column Boom SAW Welding Machine 4 sets1) Usage: For performing submerged arc welding on assembled H Beam2) Technical Parameters: (Fig.5)

5. YGJ15 Steel Conveyor 4 sets/2 groups1) Usage: For sending WIP to next station2) Technical Parameters: (Fig.6)

6. 60° Hydraulic Overturning Rack 12 sets / 4 groups1) Usage: For flipping WIP 60°2) Technical Parameters: (Fig.7)

7. YF1520 Movable 180° Hydraulic Overturning Rack 4 sets/2 groups1) Usage: For flipping WIP 180° and send to next station2) Technical Parameters: (Fig.8)

8. HYJ-40 or HYJ-800 Mechanical Motorized H Beam Flange Straightening Machine 1 set1) Usage: For straightening deformed flange after submerged arc welding2) Technical Parameters: (Fig.9)

9. Transportation Conveyor Several groups Our AdvantagesAfter Sales ServiceFAQ1. Q: What is the relationship between Wuxi AMASS and Wuxi JACK?

A: Wuxi AMASS and Wuxi JACK are the same company: Wuxi AMASS is wholly owned subsidiary of Wuxi JACK, for overseas trading Wuxi JACK products;

2. Q: What is the nature of your company?

A: Business scope of Wuxi JACK and AMASS covers design, production and selling;

3. Q: What is the range of your company product?

A: Wuxi JACK and AMASS is a professional supplier in Welding and Cutting Industry;Main products of our company include:1) Steel structure production equipment (H Beam/ BOX Beam/ T Beam);2) Edge Milling Machine;3) Structure member Beam end face milling machine;4) CNC Plate Cutting Machine;5) CNC Pipe Cutting Machine;6) Various kinds of conventional and special design welding equipment and machine;7) Various kinds of conventional and special design Straightening machine, etc.;

4. Q: What is the strength of your company?

A:1) Wuxi JACK was founded by 3 senior engineers 15 years ago;2) Engineering team of our company has over 20 years experience on Welding and Cutting industry;3) Operation manager has 14 years experience working in an American Fortune Global 500 Dow Jones Industrial Index Company as senior Project Manager;4) The competitive edge of our company is special design products based on customer demand.

5. Q: What are service terms of your company?

A:1) During business negation: a) Make technical proposal and quotation;b) Answering customer questions;c) Make final contract and technical agreement;2) During order to delivery value chain:a) Design, validate, and manufacture products for customers;b) Inform progress of manufacture to customers;c) Arrangement for package and shipment of products to customers;3) After sale service: a) Technical support on installation and commissioning at customer site;b) 1 year guarantee from the date of acceptance;c) Feedback any technical issues within 4 hours upon getting the notice;

6. Q: Where is location of your company?

A: Wuxi city, Jiangsu province, 130km from Shanghai

Basic Info.

| Model NO. | HB1500/ 1800/ 2000 |

| Certification | ISO, CE |

| Automation | Automation |

| Flexible Production | Intelligent Manufacturing |

| Rhythm | Flow Production Line |

| Production Scope | Product Line |

| After-sales Service | 1 Year Gurantee, Life Long Technical Support |

| Included Function | Cutting, Assembling, Welding, Straightening |

| H Beam Transfer | Automatic 90degree overturning |

| Project Nature | Turnkey Project |

| Working Style | Fully Automatic |

| Transport Package | Disassembled and Packed Into Wooden Case |

| Specification | For welding H Beam height 1500/ 1800/ 2000 mm |

| Trademark | Wuxi JACK and AMASS |

| Origin | Wuxi, China |

Packaging & Delivery

Package Size 10000.00cm * 6000.00cm * 400.00cm Package Gross Weight 50000.000kgProduct Description

A. Usage and Application: 1. HB series Automatic H Beam Production Line is for making welding H Beam T Beam in fully automatic way.2. Specification of produced welding H Beam: (Fig.1)| Model | HB Series Automatic Welding H Beam Production Line |

| Standard Models | HB1500/ HB1800/ HB2000 |

| Max. H Beam Web Width | 1500 mm/ 1800 mm/ 2000 mm |

| H Beam Web Thickness | 6∽32 mm |

| H Beam Flange Width | 200∽800 mm |

| H Beam Flange Thickness | 6∽40 mm |

| H Beam Length | 4000∽12000 mm |

| Max. H Beam Weight | 20 Ton. |

| H Beam Production Machine for Assembly | Z15/ Z18/ Z20 H Beam Assembly Machine with Tack Welding,CO2 Spot Welding |

| H Beam Production Equipment for SAW Welding | LHC Trolly Moving H Beam Submerged Arc Welding Machine |

| H Beam Production Equipment for Flange Straightening | HYJ-40 or HYJ-800 H Beam Straightening Machine |

| H Beam Production Machine for Transfer of H Beam workpiece among stations | Steel Structure Flipping Equipment: Flipping units/ Conveyor/ Travel Cart |

B. Advantages of Wuxi JACK (Wuxi AMASS) H Beam Production Line:

This is superior product of Wuxi JACK (Wuxi AMASS). Below slides give graphical introduction on our strong points:

C. Main Equipment in (Wuxi JACK) Wuxi AMASS H Beam Production Line: 1. CNC-CG4000A CNC Plate Cutting Machine 1 set1) Usage: For cutting steel plate into raw material2) Technical Parameters: (Fig.2) 2. Z15/ Z18/ Z20 H Beam Assembly and Tack Welding Machine 1 set1) Usage: For assembling and tack welding flange and web2) Technical Parameters: (Fig.3)

3. 90° Hydraulic Overturning Rack 3 sets/group1) Usage: For flipping WIP 90°2) Technical Parameters: (Fig.4)

4. LHC Column Boom SAW Welding Machine 4 sets1) Usage: For performing submerged arc welding on assembled H Beam2) Technical Parameters: (Fig.5)

5. YGJ15 Steel Conveyor 4 sets/2 groups1) Usage: For sending WIP to next station2) Technical Parameters: (Fig.6)

6. 60° Hydraulic Overturning Rack 12 sets / 4 groups1) Usage: For flipping WIP 60°2) Technical Parameters: (Fig.7)

7. YF1520 Movable 180° Hydraulic Overturning Rack 4 sets/2 groups1) Usage: For flipping WIP 180° and send to next station2) Technical Parameters: (Fig.8)

8. HYJ-40 or HYJ-800 Mechanical Motorized H Beam Flange Straightening Machine 1 set1) Usage: For straightening deformed flange after submerged arc welding2) Technical Parameters: (Fig.9)

9. Transportation Conveyor Several groups Our AdvantagesAfter Sales ServiceFAQ1. Q: What is the relationship between Wuxi AMASS and Wuxi JACK?

A: Wuxi AMASS and Wuxi JACK are the same company: Wuxi AMASS is wholly owned subsidiary of Wuxi JACK, for overseas trading Wuxi JACK products;

2. Q: What is the nature of your company?

A: Business scope of Wuxi JACK and AMASS covers design, production and selling;

3. Q: What is the range of your company product?

A: Wuxi JACK and AMASS is a professional supplier in Welding and Cutting Industry;Main products of our company include:1) Steel structure production equipment (H Beam/ BOX Beam/ T Beam);2) Edge Milling Machine;3) Structure member Beam end face milling machine;4) CNC Plate Cutting Machine;5) CNC Pipe Cutting Machine;6) Various kinds of conventional and special design welding equipment and machine;7) Various kinds of conventional and special design Straightening machine, etc.;

4. Q: What is the strength of your company?

A:1) Wuxi JACK was founded by 3 senior engineers 15 years ago;2) Engineering team of our company has over 20 years experience on Welding and Cutting industry;3) Operation manager has 14 years experience working in an American Fortune Global 500 Dow Jones Industrial Index Company as senior Project Manager;4) The competitive edge of our company is special design products based on customer demand.

5. Q: What are service terms of your company?

A:1) During business negation: a) Make technical proposal and quotation;b) Answering customer questions;c) Make final contract and technical agreement;2) During order to delivery value chain:a) Design, validate, and manufacture products for customers;b) Inform progress of manufacture to customers;c) Arrangement for package and shipment of products to customers;3) After sale service: a) Technical support on installation and commissioning at customer site;b) 1 year guarantee from the date of acceptance;c) Feedback any technical issues within 4 hours upon getting the notice;

6. Q: Where is location of your company?

A: Wuxi city, Jiangsu province, 130km from Shanghai

previous:

Customized Aluminum

Send to us