Automatic Flange Thickness 80mm Heavy Duty Steel Structure Beam Straightening Machine

Package Size 430.00cm * 173.00cm * 250.00cm Package Gross Weight 16000.000kg Automatic Flange thickness 80mm Heavy duty

Basic Info.

| Model NO. | JZJ-80 |

| Voltage | 380V-440V |

| Automatic Grade | Automatic |

| Principle | Deformation After H Beam Welding |

| Certification | CCC, ISO9001, CE |

| Warranty | 12 Months |

| Customized | Customized |

| Condition | New |

| Straightening Wheel Speed | 8.9m/Min |

| Delivery | 30 Days |

| Roller Hardness | HRC50-55 |

| Hydraulic Station | 1 Set |

| High Pressure Straightening Force | 2800kn |

| Function | H Beam I Beam Flange Straightener |

| Min Web Height | 350mm |

| Straightening Speed | 6m/Min |

| Straightening Mode | Hydraulic |

| Max Flange Thickness | 80mm |

| Model | Jzj-80 |

| Flange Width | 200-1000mm |

| Roller Material | 35CrMo |

| Transport Package | Nude |

| Trademark | Lemar |

| Origin | Wuxi, China |

| HS Code | 8462291000 |

Packaging & Delivery

Package Size 430.00cm * 173.00cm * 250.00cm Package Gross Weight 16000.000kgProduct Description

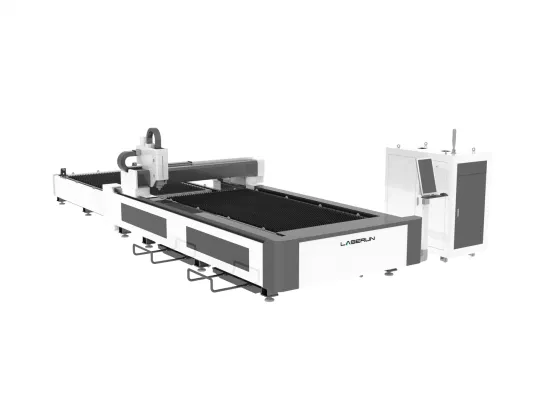

Automatic Flange thickness 80mm Heavy duty steel structure beam Straightening Machine

The H-beam flange straightening machine is a special equipment for correcting the deformation of the H-beam flange plate after welding.Automatic flange straightening machine has the characteristics of simple structure, convenient operation, high speed, high efficiency and reliable work. It can be widely used in large buildings, water conservancy bridges, metallurgy Industry and other metal structure industrial sectors.There are two options for mechanical h beam straightening machine and hydraulic h beam straightening machine.

Specification:

| Straightening thickness of flange | 80mm |

| Length of roller rack | Input/Output 9000mm*3 sets |

| Width of flange plate | 150-800mm |

| Web height | 350mm |

| Thickness of flange plate | 6-60mm |

| Height of H beam web | 200-1000mm(customized) |

| Material of H beam | Q235/Q345 |

| Total power | 25kW |

| Straightening speed | 6.3m/min |

| Working pressure | 32Mpa |

Note: With foundation or without is according to your needs.

FAQ:1. How to choose hydraulic type and mechanical type for H-beam flange plate straightening machine?We can customize the H-beam flange plate straightening machine for you according to the size requirements of the H-beam.Generally, the mechanical H-beam T-beam straightening machine is suitable for the thickness of the flange plate <=40mm, and the hydraulic steel structure straightening machine is suitable for the thickness of the flange plate 40mm~80mm.2. In addition to the flange plate straightening machine, what other equipment is required for the production of H-beam and box-beam production lines?The type of equipment and the quantity purchased need to be based on the layout of your company's on-site factory. Before purchasing the machine, we recommend that the customer send us the factory layout plan for design.A complete H-beam box beam production line includes:CNC Plasma Flame cutting machine-Automatic assembly machine with gas shield welder-Gantry type Submerged arc or gas shield welding machine-H beam flange straightener-End face milling machine.If for Box beam production need Electroslag welding machine, Box beam assembly machine and spot welding machine, etc.3. How to provide installation service?Under normal circumstances, we will arrange engineers to go to your factory for on-site installation guidance. But for now, due to the global virus outbreak, we currently offer installation instruction manuals, as well as online video instructions. These installation manuals have been able to ensure that customers can successfully complete the installation and commissioning of the machine4. How to visit your company?We can pick you up from Shanghai Pudong International Airport, Hongqiao International Airport or Wuxi Airport. Or Wuxi Railway Station.5. What should I do if the machine is broken?The warranty period for our machines is 12 months. If the damaged parts cannot be repaired, we can send new parts to replace the damaged parts, but you need to pay for the courier yourself. After the warranty period, we can negotiate and provide technical support for the entire life cycle of the equipment.6. Can you be responsible for shipping?Yes, please tell us the port of destination or address. We have rich experience in transportation. FOB, CIF or EXW will do price calculation according to your needs.7. Do you provide OEM service?Of course, we can design equipment based on the structural section data you provide. We are a professional designer and manufacturer of H-beam production line equipment and automatic pipe welding equipment.

Send to us